The post Shapeways Acquires Majority Stake in 3D Mannequin Platform Thangs appeared first on CreditLose.

]]>Shapeways has acquired the 3D file sharing platform Thangs from Physna, Inc. The announcement is marking the second section of Shapeways’ relaunch below new administration. The acquisition goals to deal with infrastructure gaps in Shapeways’ earlier market system.

The combination will enable Thangs to function as a subsidiary below the title Thangs 3D Inc., whereas sustaining its current group and performance. Thangs at the moment hosts an index of over 24 million 3D printable fashions and gives IP safety via Physna’s know-how. The platform will function the consumer-facing model for creators and makers.

The merger creates new alternatives for each platforms’ consumer bases. Designers utilizing Thangs will acquire entry to Shapeways’ manufacturing capabilities, enabling them to promote bodily merchandise on to shoppers. Shapeways CEO Marleen Vogelaar stated: “The group behind Thangs actually love their creators and group — they usually take excellent care of them: which is precisely in step with the unique spirit of Shapeways.”

Below the brand new construction, Shapeways will concentrate on enterprise prospects whereas supporting Thangs’ consumer-oriented companies. The corporate plans to implement a ‘Print to Shapeways’ button inside the Thangs platform and develop new store options. Each platforms will make the most of Shapeways’ digital manufacturing engine, which operates below ISO:9001, IATF 16949, and ISO 14001 requirements.

Former Shapeways group members and new customers can discover monetization alternatives via the Thangs platform at thangs.com/memberships. The mixed ecosystem now spans your complete 3D creation worth chain, from design conception to bodily manufacturing. This integration permits creators to take care of their digital asset companies whereas increasing into bodily product gross sales.

[ad_2]

The post Shapeways Acquires Majority Stake in 3D Mannequin Platform Thangs appeared first on CreditLose.

]]>The post Ursa Main’s New 3D Printed Strong Rocket Motor Completes Profitable Flight Check appeared first on CreditLose.

]]>A protracted-range stable rocket motor (SRM) developed by rocket engine producer Ursa Main and Virginia-based Raytheon Applied sciences has accomplished profitable missile flight testing for the US Military. The motor has thus far been flown twice with Raytheon at Naval Air Weapons Station China Lake.

Ursa Main’s Lynx 3D printing know-how was used to fabricate the SRM. This, together with Raytheon’s digital engineering capabilities, enabled the companions to speed up improvement instances and lower manufacturing prices.

Daniel Jablonsky, Ursa Main’s CEO, defined that the agency has utilized additive manufacturing to realize “unprecedented timelines,” with practically 300 SRM static take a look at fires accomplished in 2024 alone. For this newest mission, the workforce went from idea and design to firing and flight in beneath 4 months, which Jablonsky referred to as “lightning quick.” He added that 3D printing has facilitated the manufacturing of “agile stable rocket motor options with the design flexibility wanted to develop the capabilities of the US navy.”

Within the US, demand for SRMs is coupled with a scarcity of home suppliers. Provide chain challenges are impacting the US Division of Protection (DoD)’s efforts to restock inventories and help ongoing battle efforts in Ukraine and Israel. The Pentagon’s annual finances request for missile and munitions procurement, in addition to associated analysis and improvement, elevated from $9 billion in 2015 to $30.6 billion in 2024.

Jablonsky famous that Ursa Main’s know-how will scale SRM manufacturing “on the tempo and quantity the nation requires and at a value the nation can afford.”

3D printed SRM completes profitable flight take a look at

RTX Ventures, Raytheon’s enterprise capital division, first invested in Ursa Main in 2023 to develop its SRM manufacturing capabilities and tackle the US navy’s want for inexpensive precision-guided missiles.

Ursa Main’s Lynx know-how combines metallic 3D printing with product-agnostic tooling to manufacture a number of SRMs concurrently in the identical manufacturing line. Typical SRM manufacturing processes are troublesome to re-tool, costly to ramp up, and depending on massive workforces. Lynx streamlines this course of, introducing versatile and scalable manufacturing capabilities that unlock higher-volume SRM manufacturing at a fraction of the value.

Raytheon and Ursa Main declare that the additive manufacturing-based method will ship “a brand new era of sensible munitions” for the US Military. These new weapon methods will reportedly be considerably extra inexpensive than presently fielded, conventionally manufactured munitions.

The profitable US Military take a look at demonstrates the long-range missile supply capabilities of the businesses’ 3D printed SRMs. Tom Laliberty, president of Land and Air Protection Techniques at Raytheon, said that these motors will enable the US and its allies “to strike farther and sooner than something our adversaries have of their arsenals.” He added that the SRMs present “inexpensive precision fires, whereas growing vary, security, and journal depth.”

Trying forward, the subsequent section of this system will see Ursa Main and Raytheon enhance the manufacturing course of, with an extra flight take a look at deliberate for 2025 and qualification in 2026.

In a separate mission, Ursa Main obtained $12.5 million from the US Navy and the Workplace of Strategic Capital (OSC) to scale the manufacturing of 3D printed SRMs. By means of the prototype mission settlement, the corporate is designing, manufacturing, and testing a brand new SRM prototype for crucial missiles. This adopted the information that the corporate is 3D printing the Navy’s Mk 104 twin rocket motor, which powers the SM-2, SM-3, and SM-6 missiles.

3D printing missile methods

Ursa Main and Raytheon will not be the one corporations 3D printing missile methods for the US DoD. Earlier this yr, Italian rocket and missile producer Avio introduced plans to triple its manufacturing of SRMs over the subsequent 4-5 years to handle rising US demand.

Whereas the function of additive manufacturing on this initiative hasn’t been confirmed, the corporate actively makes use of 3D printing to supply propulsion methods. The agency possesses Velo3D Sapphire 3D printers to manufacture high-strength, corrosion, and temperature-resistance components in nickel-based alloy supplies. Avio beforehand partnered with Raytheon to construct a home industrial base for crucial SRMs. It’s now constructing a US-based manufacturing facility to strengthen provide chains and diversify sourcing choices.

Elsewhere, US Protection agency Lockheed Martin is 3D printing key parts of its new Mako hypersonic missile. Steel additive manufacturing know-how is getting used to manufacture the jet-fired missile’s steering part and fins, unlocking important time and value financial savings. The steering part is 3D printed ten instances sooner than standard strategies whereas being simply 1/tenth of the price.

Work on Mako began in 2017, with the missile now at readiness stage six plus, that means it’s prepared for manufacturing. Weighing 1,300 kilos, it has been externally fit-checked on F-35, F/A-18, F-16, F-15, and P-8 plane, with inside fit-checking accomplished on the F-22 and F-35C fighters. Its stable rocket motor (SRM) can speed up Mako to Mach 5.

Who gained the 2024 3D Printing Business Awards?

All of the information from Formnext 2024.

Subscribe to the 3D Printing Business e-newsletter to maintain up with the most recent 3D printing information.

You too can comply with us on X, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture reveals an Ursa Main SRM being examined. Photograph through Ursa Main.

[ad_2]

The post Ursa Main’s New 3D Printed Strong Rocket Motor Completes Profitable Flight Check appeared first on CreditLose.

]]>The post Shapeways Buys 3D Mannequin Neighborhood Thangs – 3DPrint.com appeared first on CreditLose.

]]>3D printing service pioneer Shapeways is exhibiting vital initiative. Simply weeks after rising from chapter, the corporate is buying Thangs, a platform for downloading and sharing designs, from Physna, Inc. Thangs permits customers to promote designs and share them globally. The platform additionally allows creators to cost memberships for unique entry, supply affiliate income to promoters, and conduct searches throughout Thangs and different sharing platforms.

This acquisition might present Shapeways with substantial income from digital file gross sales and doubtlessly drive bodily element gross sales. For customers, the improved Thangs platform might scale to accommodate high-volume manufacturing utilizing powder mattress and different manufacturing processes.

Shapeways mentioned of the deal:

“Modifications to the Shapeways enterprise mannequin by the previous administration crew left the infrastructure underpinning Outlets and Market outdated. The acquisition of Thangs from Physna, Inc., supplies the neighborhood with a well timed answer that exceeds Shapeways’ prior capabilities combining strong IP safety powered by Physna’s expertise with a contemporary platform tailor-made to creators’ wants. With Thangs fostering concepts into designs and Shapeways bringing these designs to life, the 2 firms collectively create a seamless ecosystem that spans the total 3D creation worth chain.”

“The crew behind Thangs actually love their creators and neighborhood — and so they take excellent care of them: which is strictly in step with the unique spirit of Shapeways. Equally importantly their 3D search expertise powered by Physna protects the IP of their creators which is extremely essential to me and the remainder of the administration crew. We shall be working now to create the ‘Print to Shapeways’ button inside Thangs, and creating outlets. We shall be retaining the spirit of Thangs, which is able to develop into Thangs 3D Inc., a subsidiary, whereas creating a brand new house for Shapeways neighborhood members’ 3D information and companies,” Shapeways CEO Marleen Vogelaar said.

“The synergy between Shapeways and Thangs was clear from the beginning. Whereas Physna will proceed to focus totally on our B2B and authorities merchandise, we stay invested in Thangs and have an amazing relationship with the neighborhood. We sit up for persevering with to assist Thangs and Shapeways; I imagine the sturdy synergies between the 2 will drive progress and create worth for each communities,” added Paul Powers, CEO and Co-founder of Physna, Inc.

I hope Shapeways invests in creating desktop 3D printer-based print farms as nicely. This strategy would allow them to compete with the rising variety of print farms rising globally. Whereas powder mattress fusion excels at producing detailed components in giant portions, dependable desktop 3D printers can create inexpensive components in a wide range of supplies at comparable scales.

At the moment, there’s a worth hole in 3D printing being exploited by firms like Gantri and different 3D printed lamp producers. With well-designed 3D printed lamps now obtainable at inexpensive costs, dozens of corporations are getting into this market. Many use desktop machines to print their merchandise, both in-house or via companies like Slant3D. This pattern indicators the broader potential for desktop 3D printing in end-use components.

Shapeways might strategically place itself as the one service able to mastering each desktop and industrial 3D printing, bridging the hole between affordability and scalability. This transfer not solely reinforces Shapeways’ adaptability but additionally highlights its potential for future progress.

Subscribe to Our E mail E-newsletter

Keep up-to-date on all the most recent information from the 3D printing trade and obtain data and gives from third occasion distributors.

[ad_2]

The post Shapeways Buys 3D Mannequin Neighborhood Thangs – 3DPrint.com appeared first on CreditLose.

]]>The post Case Research: Jap Rail Company appeared first on CreditLose.

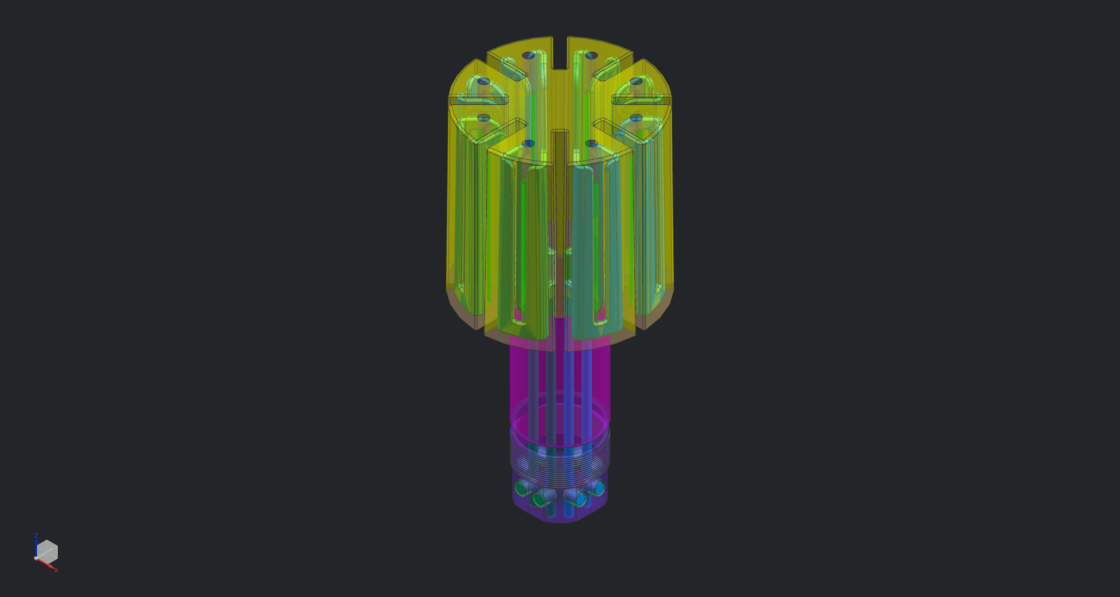

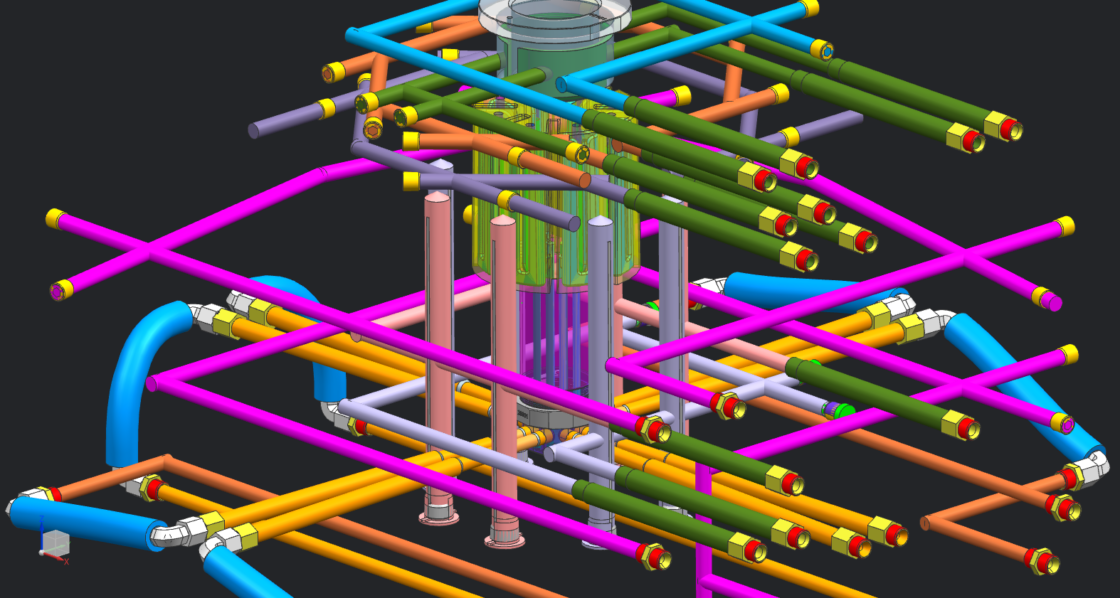

]]>Enhancing Injection Molding Effectivity with Conformal Cooling

Based in 2007, Jap Rail Company constructed a fame on designing sustainable, high-quality options for the Metro Rail infrastructure within the US. For a particular element—an insulator that isolates the electrified third rail in underground subway programs–Jap Rail wanted to replace the fabric to satisfy security requirements. A change to Polyphenylene Sulfide (PPS) subsequently required a reevaluation of the prevailing mould. To sort out this challenge, Jap Rail approached Linear AMS, a Shapeways Firm, in search of partnership in creating an revolutionary answer to reinforce performance and effectivity.

Jap Rail is a long-standing buyer, supporting transit companies in metropolitan areas like New York Metropolis, Washington, D.C., and Miami, the place city rail programs steadily function in underground tunnels. Such an setting calls for elements with particular dielectric properties, safeguarding towards undesirable electrical expenses and permitting for simpler administration of underground prepare strains.

Incorporating Superior Cooling Know-how

Injection molding producers typically face challenges associated to lengthy cycle occasions, half high quality, and general effectivity. Conformal cooling expertise particularly resolves these issues. Counting on 3D printing for personalisation and effectivity, conformal cooling adapts to suit into industrial molds.

In distinction to traditional strategies, that are restricted to machining in straight strains, conformal strains are designed to comply with the form of the half itself–resulting in a extra constant temperature all through the half’s cooling stage. Which means elements are much less prone to warp, whereas additionally cooling as much as 50% sooner. With conformal cooling, producers can scale back their cycle time and improve their throughput, all whereas enhancing half high quality.

For Jap Rail, integrating this expertise produced extra constant temperatures in tooling, resulting in extra environment friendly manufacturing cycles, satisfying stringent necessities for dependable and environment friendly rail programs.

Enhancing Tooling for Complicated Supplies

Initially, Jap Rail encountered challenges as a result of complicated half design and core mould options, mixed with the character of Xencor PPS LGF-3045, a forty five% long-glass, fiber-reinforced Polyphenylene Sulfide (PPS).

PPS LGF-3045, a forty five% long-glass, fiber-reinforced Polyphenylene Sulfide (PPS).

Whereas offering useful properties like warmth resistance and sturdiness, PPS additionally presents manufacturing difficulties. Linear carried out a complete evaluation, revealing that Jap Rail’s current tooling with standard cooling–together with a PPS materials–wouldn’t produce a moldable half.

“I used to be conscious a brand new method can be needed with the change in materials,” mentioned Mickey Morales, CEO of Jap Rail. “After working with Linear for the previous decade, I used to be assured of their engineering experience and knew they had been able to delivering the dynamic answer this challenge wanted.”

To deal with these points, Linear and Jap Rail labored side-by-side for months in prototyping and testing, experimenting with molds and the combination of 3D printed conformal cooling strains.

Upon preliminary evaluate, the group advised making the change to a metal mould over aluminum for manufacturing volumes. The PPS materials is extremely corrosive and would deteriorate the aluminum mould. Transitioning to a metal mould additionally opened up the potential for utilizing conformal cooling to permit for higher thermal management. Moreover, based mostly on the molding temperature necessities of PPS, the group decided scorching oil can be needed to keep up software temperature, versus water which is extra generally used.

“The shift to metal molds considerably reworked our method, working a lot better with the distinctive traits of PPS and the necessity for a exact, managed molding setting,” mentioned John Tenbusch, Director of Automotive Gross sales at Shapeways.

“After working with Linear [A Shapeways Company] for the previous decade, I used to be assured of their engineering experience and knew they had been able to delivering the dynamic answer this challenge wanted.”

Mickey Morales, CEO of Jap Rail

Lowering Cycle Instances & Enhancing Half High quality

The introduction of conformal cooling was extremely efficient, yielding a exceptional enchancment in effectivity after Linear launched metal tooling. Implementing conformal cooling led to a design adjustment that considerably reduce prices. Interchangeable inserts, normally requiring three cores, had been diminished to only one.

“We needed to incorporate cooling a method or one other,” mentioned David Dickerson, Supervisor of Consumer Providers at Shapeways. “With out conformal cooling, we couldn’t have made the interchangeable elements we would have liked for the assorted sizes of the insulator.”

With the brand new metal molds and conformal cooling inserts, the Linear group was in a position to scale back the cycle time from 181 seconds to 138 seconds, reflecting a 23% enchancment. Lowered manufacturing time permits for extra elements to be made, reducing each piece price and general program price, with out sacrificing half high quality. The extra even, managed temperatures additionally led to the manufacturing of higher-quality, extra dependable elements.

Whereas the preliminary prototyping and testing part required vital time and monetary funding, the fee financial savings over the long run greater than justified the upfront expenditure. The improved materials sturdiness, decrease upkeep wants, and elevated manufacturing speeds collectively contributed to vital long-term financial benefit for Jap Rail.

“Whereas we encountered a number of obstacles throughout our journey, Linear’s group of specialists was once more in a position to present a extremely engineered answer whereas offering cost-saving advantages,” mentioned Mickey Morales, CEO of Jap Rail.

Aligning with Regulatory and Environmental Concerns

Jap Rail’s openness to new options enabled enhancements with each quick and long-term advantages, assembly industry-specific wants whereas sustaining a dedication to environmentally pleasant supplies and regulatory compliance.

This case examine presents helpful problem-solving insights for points associated to supplies, tooling, and cooling. These options could also be relevant to different manufacturing sectors as effectively. Total, this challenge showcases the worth of teamwork, innovation, and excellence in manufacturing

Discover out extra about how Shapeways can collaborate together with your firm.

[ad_2]

The post Case Research: Jap Rail Company appeared first on CreditLose.

]]>The post STL file Evil King’s Fort 🏰 ・Mannequin to obtain and 3D print・Cults appeared first on CreditLose.

]]>The floating fortress of the King of Evil…

Have a good time this 12 months’s Halloween with this particular mannequin, with particulars impressed by a location in The Legend of Zelda: Ocarina of Time.

All the things prints totally with out helps, elements will be printed individually and assembled after.

Take a look at our different Ocarina of Time areas , we have now the objective of finishing the entire overworld (and a few dungeons)!

We’re blissful to convey these fashions to life and have a good time Halloween with you. MiniWorld3D is the gathering of 3D printable landmarks and fashions of the true and fantasy world! All our fashions are produced from scratch by hand and mind.

In the event you like our work, please take into account becoming a member of our Patreon or Printables.com Membership for speedy entry to retailer fashions like this one, and unique new ones each month, together with reseller licenses!

Discover all our profiles, YouTube channel & social media on:

linktr.ee/miniworld3d

Observe MiniWorld3D on IG!

instagram.com/miniworld3d

We’re additionally on Patreon!

patreon.com/MiniWorld3D

MiniWorld 3D is a collective of 60+ artists creating one of the best library of 3D printable fashions of landmarks of the world!

This mannequin was created by Dany Sánchez.

Print & photograph credit: printed by Dany Sánchez in a Prusa MK4 & BambuLab X1 Carbon, utilizing Prusament Galaxy PLA and SpiderMaker matte PLA orange, 0.2mm, 100% scale, 12% lightning infill.

This can be a fan interpretation, no copyright infringements supposed.

Re-selling these information on-line, or promoting bodily prints on platforms like on Etsy with no Reseller License issued by MiniWorld3D is strictly forbidden, authorized motion can be taken. If you’re focused on promoting this, ship us a message, we have now enticing Reseller License plans in Patreon and Printables Membership the place all of us can win.

[ad_2]

The post STL file Evil King’s Fort 🏰 ・Mannequin to obtain and 3D print・Cults appeared first on CreditLose.

]]>